Orkla Health

New sustainable packaging system

Orkla Health is supporting a circular economy by launching a new iconic package for their dietary supplement brands. The new concept is produced using 48-100% recycled plastic, with a label in plastic from renewable resources. In less than two years, Orkla will replace the packaging for more than 240 dietary supplement products in 20 brands in 8 countries. Through this, Orkla will reach an annual emissions saving of approximately 17 tonnes and contribute to achieving the UN’s sustainability goals.

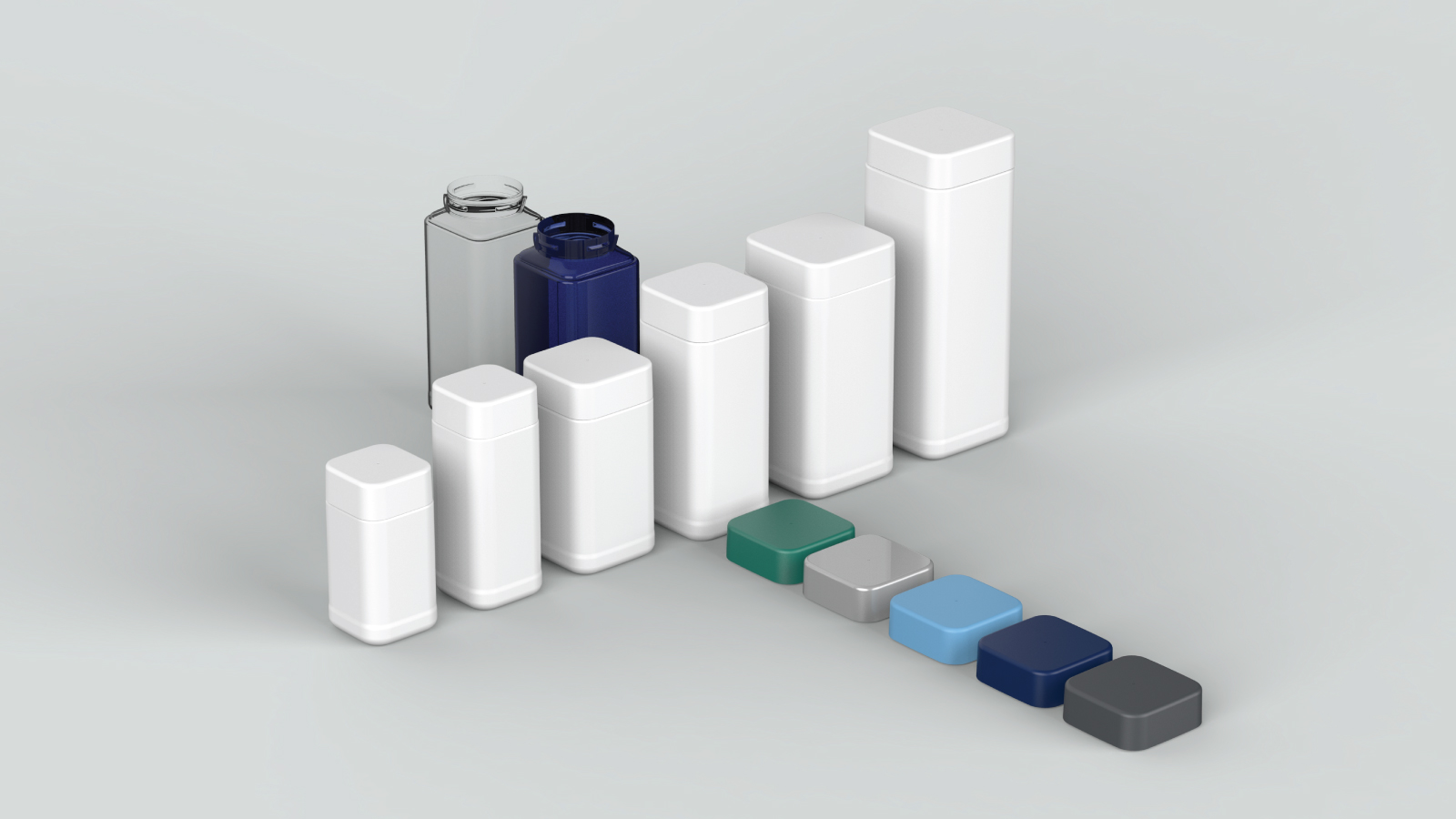

Before this work began, there were 29 different package types (comprising different sizes and materials) in the factory. This caused a high degree of complexity and complicated possibilities for a more sustainable offering. Orkla was ready to upgrade the factory in order to produce a more environmentally responsible solution. The mission was to design a new modular concept which could work in the factory as well as across many markets and brands.

The heart of this project has been to make the packaging more sustainable, and it was done in a holistic way – reviewing everything from material, form and usability, to production and logistics. The key for sustainability to succeed, is designing a holistic packaging solution, that also engages and establishes a close relationship with the consumer in usability, as well as making the right choices for re-use or disposal. With respect for environment, the compactness of people’s homes and an increasing demand for e-commerce, the team decided to explore simplicity early in the process. In a world where people have too many things, too many choices and too little time, the non-essential elements were removed. So, a compact square shape was created, which is more streamlined for storage and environmental footprint than circular-shaped packages. Also the importance of improving ergonomics was considered through redesigning the opening experience. The square shape makes the package easier to grip and to open.

The new package consists of recycled plastic (R-PET). New labels, now made of bio-based plastics, were created for the packages. To make the packages more space-efficient and reduce emissions during transport, the package shape is square. The production of the new packages will also be more climate-smart. Approximately 80 percent less energy is required for the production of packages of recycled plastic compared to packages made of new plastic. The lids are initially made of fossil plastic, as the quality requirements have not yet been met with other materials.

In a world where sustainability is growing in importance, people are subconsciously (and consciously) searching for natural cues in packaging which includes eco-smart shapes, material choices, and other new signifiers. For example, the recycled plastic gives a slight greyish tone to the plastic of the new packaging, which, a couple of years ago, would probably have been evaluated as imperfect, but today, this quality is perceived as evidence of being part of a circular economy.

Client: Orkla Health

Design team: Kristina de Verdier, Jonas Lundin, Pär Wolfner

Pictogram

Modular system

Ergonomic design

3D-printed prototypes

Circular materials